Services

Failure Analysis

Failures have a chain reaction of cause and effect, and by looking at the effect, we can understand the cause. Forensic analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. Using relative standards, the scientific method, and years of experience, we can make reliable conclusions on a cause of failure. Our experience lets us preemptively rebut defensive arguments, strengthening our clients’ positions, and allowing them to recover more than they previously thought possible.

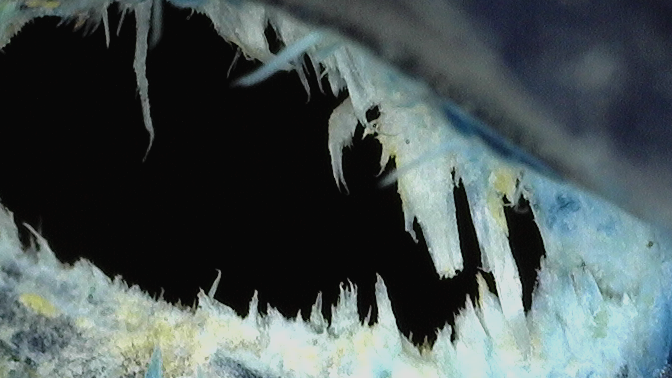

There are many forms of damage-causing effects that can result from the failure of a product, of which, fire-causing failures are one of the most significant. Determining the source of ignition and first material to ignite are key to understanding the cause of the failure and fire. Using the same forensic analysis process, the cause of failure can be determined.

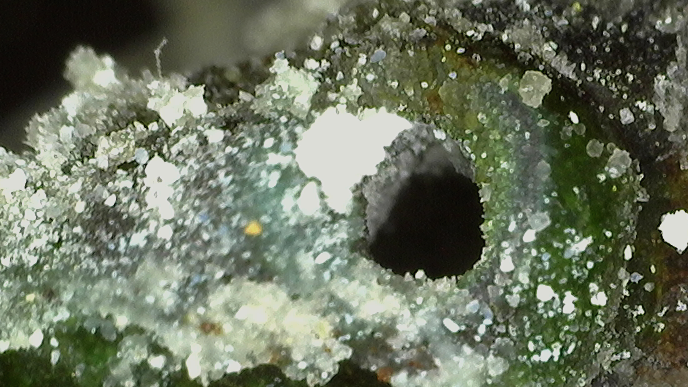

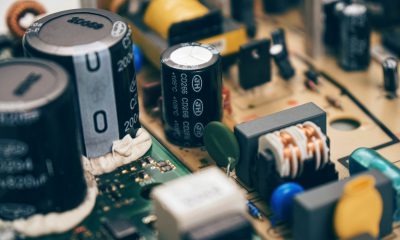

The forensic analysis process can be applied to any product, including electronics. Electronics are integral to the functionality of numerous devices and electronically powered products in our daily life. The effect of a failed electrical component can cause significant damage in many forms. Being able to determine what failed is important, but why it failed it not as easy, which is why forensic engineering is required. Furthermore, being able to eliminate other causes, for example lightning damage, makes the conclusion even stronger and more reliable.

All our standard nondestructive examinations are set at a flat fee! You don’t have to worry about expensive exemplar testing or hourly rates!

Our Other Industry-Focused Services!

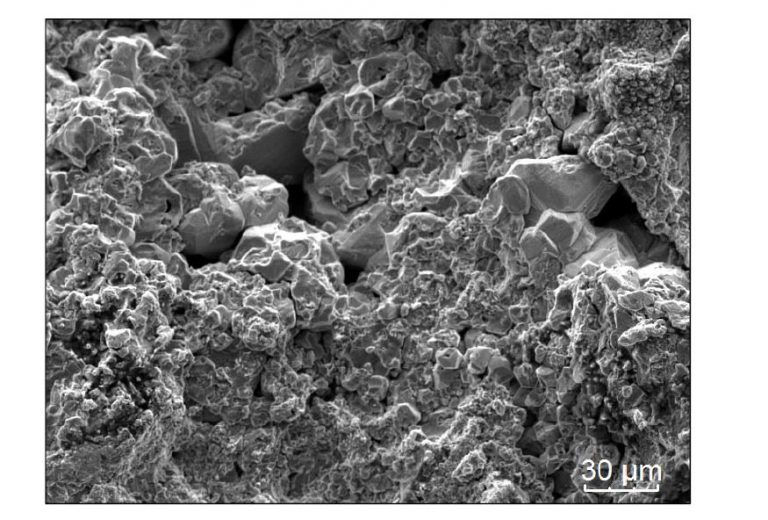

Material Testing

Veritas Engineering has teamed up with experts in metallurgical testing, and our collaborative efforts produce effective results for every project. We can source and coordinate with metallurgical experts to get the comprehensive analysis you need.

Expert Witness Services

You need engineers who can not only determine the cause of the failure but also effectively argue what the evidence indicates.

Advanced Imaging

Veritas Engineering has teamed up with experts in advanced imaging, the collaborative efforts of which produce effective results for every project. We can source and coordinate with advanced imaging experts to get the comprehensive analysis you need.

Employee Training

Water losses cost U. S. insurers approximately $112 billion annually, but many of those claims have very high potential for recovery. The Veritas Engineering Water Loss Training Series gives personnel—from property adjusters to subrogation specialists—the tools you need to yield higher recovery on more claims.

Logistics and Storage

You are busy enough. Save a trip to the loss location by letting us handle the details of pickup, packaging, and shipping. Let us help you with your storage needs. Every examination comes with a period of complimentary storage.

Areas Served

We serve a diverse range of needs and requirements. Veritas Engineering has produced effective results for law firms, insurance carriers, and subrogation services clientele.

On-Site Examinations

Sometimes the circumstances require an engineer to examine the failure site and installed location. Veritas has you covered.

FEA and Moldflow Analysis

Finite Element Analysis (FEA) is the simulation of any given physical phenomenon using a numerical technique called the Finite Element Method (FEM). The details of injection molding plastic are difficult to visualize. Moldflow analysis creates impressive graphics and animations that show the flow of plastic in an injection mold.